Rigid Flex 10 Layer

Black Material

Burn in Board

Flex with Rogers Material

| Attribute | Standard | Advanced | R & D |

| Line space | .005 | .004 | .003 |

| Copper Foil mix/max | .5/1.0 | .5/8.0 | 10.0 |

Pad size internal (diameter over drill) |

0.014 | 0.008 | 0.008 |

Pad size external (diameter over drill) |

0.012 | 0.008 | 0.008 |

| Drilled Hole min. | 0.010 | 0.008 | 0.006 |

| Plated Hole min. | 0.012 | 0.010 | 0.008 |

| Aspect Ratio | 8:1 | 8:1 | 8:1 |

| Plated Hole Tolerance | +/- .003 | +/- .002 | +/- .002 |

| Hole-to-Image Tolerance | .006 +/- | .004 +/- | .004 +/- |

| Hole plated Size Tol. | .003 +/- | .003 +/- | .003 +/- |

| Hole Unplated Size Tol. | .002 +/- | .002 +/- | .002 +/- |

| Max Board Thickness | 0.125 | 0.250 | 0.250 |

| Min Board Thickness | 0.012 | 0.008 | 0.006 |

| Max Copper Weight | Internal | 3.0 | External 10 |

| Max Layers | 24 | 34 |

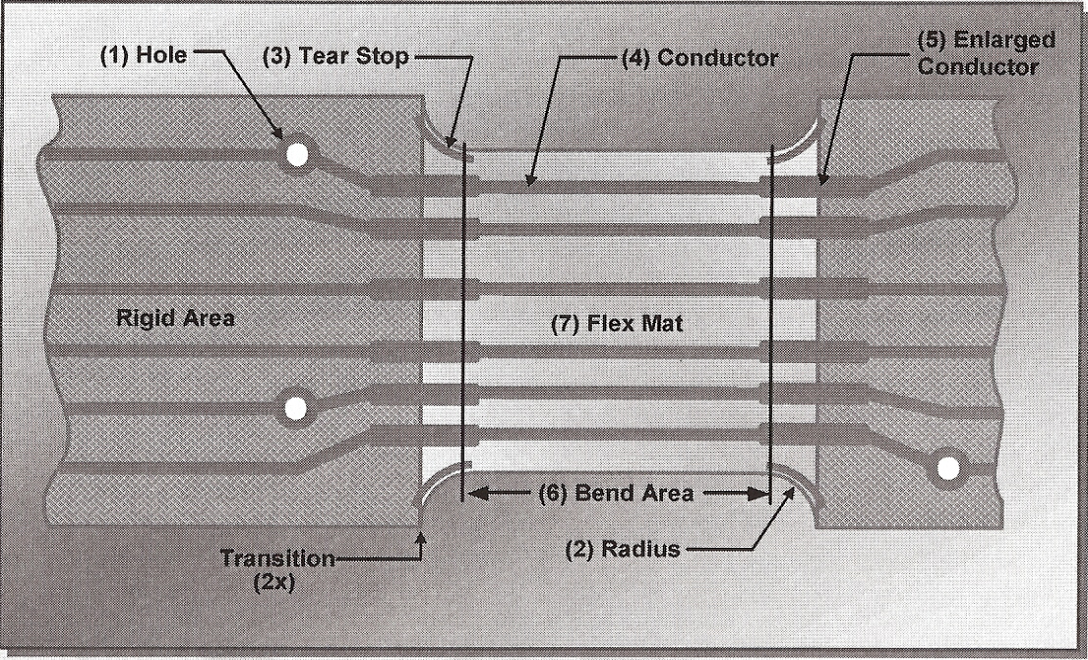

Preface: The following is a quick design guideline for Rigid Flex and is directly related to the flex portion of the PWB. Due to the custom nature of every design, this guide intended to be presented by the highly experienced PCWI team.

- HOLE. Is recommended to be located at least 0.075 zone is where rigid adhesive and flex cover meet and may impact the integrity of metallized holes

- RADIUS. Minimum value to be 0.060” to transfer the point of bend away from the sharp transition line

- TEAR STOP. Is recommended whenever space is permitted to reinforce the critical area from tearing

- CONDUCTOR. A) Must be at least .050” from the edge of t flex B)Always

- ENLARGED CONDUCTOR: Where possible, conductor should be enlarged through the transition and bend lines for added strength

- END AREA or length is calculated by multiplying the thickness of the flex by 10 for 90 degree bend and by 12 for 180 degree. Bend area should be no less than .030”

- LEX MATERIAL. Matching the material to the application is the most important note on the Fab

Drawing. The following is the ranking from the Best to the risky: A) AP adhesiveless, B) LF kapton acrylic, C) FR fire retardant, D) FR4 rigid material. This area is best discussed with PWB fabricator (PCWI)